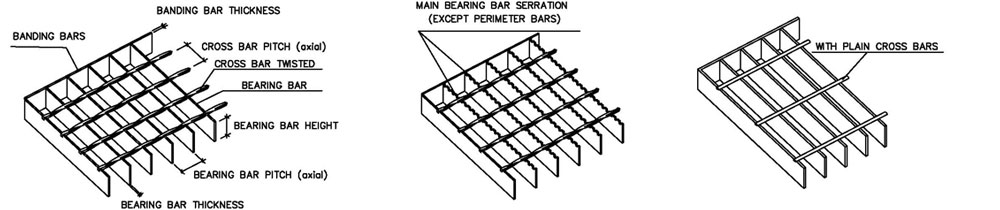

Forge-welded Gratings

Each individual intersection of the bearing bar and cross bar are welded, securing to maintain the physical and mechanical characteristics of the grating after any processing and under any condition These gratings are extremely stable with optimal load distribution.

We manufacture gratings in panels with bearing bar thickness up to 5 mm and bearing bar spacing 15 mm, 25 mm, 30 mm, 34 mm, 41 mm and 43 mm, as well as their multiples such as 50 mm, 60 mm and 68 mm.

The gratings are available with standard pitches 34x38 mm and 34x51 mm (DIN 24537-1) – as well as with 34x76 mm, 34x100 mm, 30x100 mm and 30x38 mm, 30x51 mm, 30x76 mm 41x100 mm as well as 41x51 mm 34x24 mm suitable for a ball with diameter 20 mm 25x76 mm as well as 25x100 mm 15x76 mm

The cross bar can be round or twisted (except in the case of 15x76 mm being only round and with 4 mm diameter).

The bearing bars can be serrated on their upper part.

Full serration means that even the two side bars of the panel are serrated.

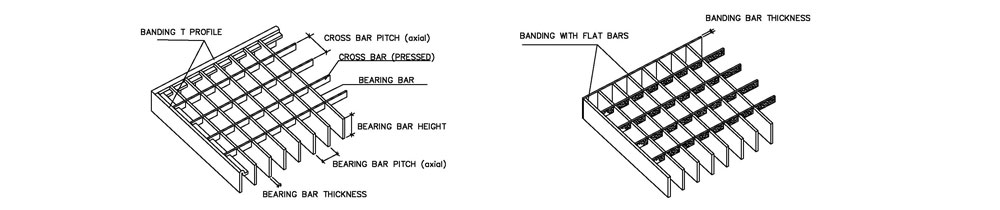

Press-locked gratings

Press-locked gratings are manufactured with specially notched bearing bars and cross bars inserted in the special notch with high pressure in specific distances between each other, forming appropriate square or rectangular meshes.

This production method secures a fast, affordable and qualitative production of gratings, without welding the intersections and gives the possibility for very narrow meshes. The standard dimensions are edged with a specially shaped banding of T-profile.

Press-locked gratings are appropriate for architectural applications and special cases for pedestrians.

The production line is designed for a great variety of meshes, and press-locked gratings can be manufactured with additional anti-skid design with serration on the upper part of the bearing bars and also on the cross bars.

Maximum dimension of the grating 2000x2000 mm Bearing bar height from 20 mm up to 50 mm Bearing bar thickness 2 mm or 3 mm

The gratings are available in standard meshes (axial) 33x33 mm (DIN 24537-1) - 33x11 mm – 50x11 mm

Press-locked Gratings with double-notch (Full Gratings)

hese gratings bear this name because the bearing and cross bars have the same cross-section , therefore have equal height

They are proposed in thickness 2-5 mm and height more than 40 mm

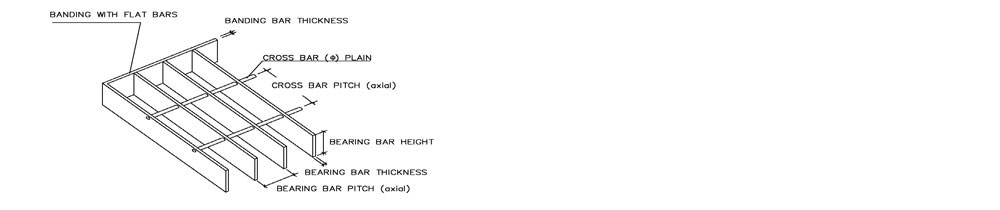

Interpenetrated Gratings

These gratings are manufactured with longitudinal flat bars and straight round cross bars, without welding or pressing, but by penetrating the cross bars into the pre-shaped holes in the middle or the upper part of the longitudinal flat bars and in specific distances between themselves, forming square or rectangular meshes.

This is a rather workshop method of production, therefore it is more flexible regarding the range of gratings and fences produced.

The Interpenetrated Gratings are more appropriate for smaller orders with many different final dimensions. For additional anti-skid effect the longitudinal flat bars can be serrated.

We propose cross bar spacing 76-100 mm with bearing bars 3 – 8 mm.

This type of grating is appropriate for heavy-duty and extra heavy-duty gratings for vehicles.

In the case of bearing bar thickness from 3 mm to 5 mm they can be serrated on the upper part of the bearing bar.

We can also produce Interpenetrated gratings in stainless steel Quality - AISI 304- for Food & Chemical Industries -Waste water Treatment Plants etc.

Sunshades – Building Facades with Grating

Gratings for sunshades and building facades (bioclimatic and building energy upgrading, etc.) Forge-welded or interpenetrated gratings in a big combination of bearing bars and meshes.